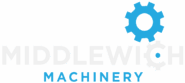

Cylinder Mower Sharpening and Grinding Services

What is Cylinder Grinding or Cylinder Sharpening ?

Cylinder grinding involves the sharpening of the cylinder and bottom blade, essentially sharpening them, restoring their edges, and aligning the angles back to the original manufacturer’s specifications.

The cylinder grinding process returns the machinery to factory standards, ensuring it’s sharp enough to efficiently cut the grass.

Importance of Cylinder Grinding in Ground Care Machinery Maintenance

The significance of cylinder grinding lies in maintaining the health of turf. It directly impacts the well-being of the grass. The primary goal is to achieve a clean cut on the leaf of the plant.

When grass is cut cleanly without any ridges or tearing of the grass plant, it’s a sign of a sharp blade. Conversely, a dull blade results in yellow and white strands of grass, indicating tearing of the grass.

Cutting grass with dull blades not only affects aesthetics, leading to a yellowish or whitish appearance but also creates an opportunity for disease.

The grass blade effectively becomes an open wound, inviting diseases, especially in extreme conditions like high humidity.

Maintaining sharp blades is akin to a surgeon wielding a sharp scalpel—it’s crucial for both appearance and the overall health of the turf. Besides appearance and disease resistance, it impacts the fuel economy of the machinery and reduces wear and tear on various machine parts, including bearings and wearing components.

Why do Golf Courses or Bowling Greens use Cylinder Mowers?

Ground care machinery mowers utilising cylinder grinding are primarily found in settings like golf courses, bowling greens, football and cricket grounds. These machines cater to the fine turf sector, ensuring a high-end finish that’s comparable to the best in grass cutting.

This precision cutting not only enhances the appearance but also affects the performance of ball sports. A smoother surface, courtesy of well-maintained sharp blades, allows balls to roll faster, significantly impacting the speed and overall quality of play.

In essence, cylinder grinding is essential for sports like golf, football and bowling where smooth, well-cut grass directly influences the speed and performance of the game. A well-maintained grass surface ensures a faster, smoother, and more enjoyable experience for players. The speed of a freshly cut golf green is drastically increased. It’s a significant factor influencing the pace and playability of the green. A precisely cut green enhances the overall experience and performance on the course, creating a smoother, faster playing surface that golfers appreciate.

These machines are vital for greenkeeping and turf maintenance in various sports settings, providing specific cutting capabilities to ensure the highest standards of turf quality and playability.

Examples of mowers that have cylinders

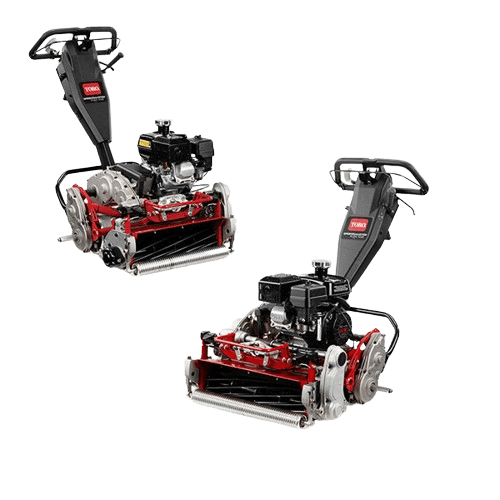

Greens Mower

This specialised mower is used on golf greens, providing precise and fine cutting for the putting surface.

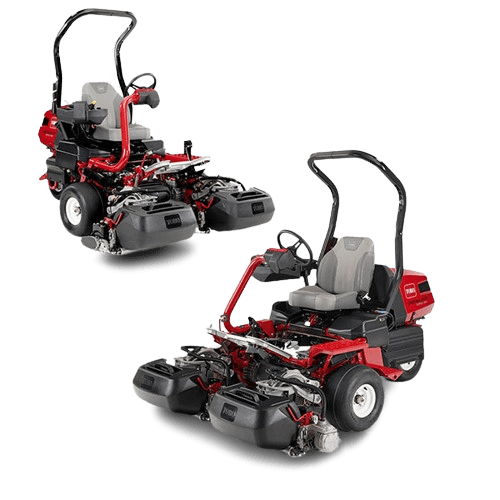

Fairway Mower

Larger than the greens mower, it's designed for cutting the fairways on golf courses, ensuring a consistent and well-maintained surface.

Apron and Tees Mower

Specifically crafted for trimming aprons and tees on golf courses, offering precision cutting for these areas.

Cricket Square Mower

Specifically designed to cut and maintain the playing surface on the cricket square, ensuring a flat and even pitch.

Football Grounds Mower

These machines keep your football pitch in prime condition and makes the famous striped finish.

Cricket Outfield Mower

Similar in function to a fairway mower, it's tailored for maintaining the outfield in cricket, ensuring a well-groomed playing field.

Components Involved in Cylinder Grinding

The fundamental components in cylinder grinding are the cylinder itself and the bottom blade, also called a bed knife or a stationary blade.

The bottom blade rests underneath the cylinder, creating a scissor-like mechanism or a shearing action essential for effective cutting. While the cylinder rotates in a circular motion, the bottom blade remains stationary. These components are ground and sharpened separately, each requiring distinct processes and machinery.

Bottom Blade Grinding Process

When focusing on the bottom blade, the primary goal is to achieve a flat and consistent surface from left to right, free from any undulations or irregularities. This flatness ensures a uniform and effective cut. Equally crucial are the angles on the front face and the bottom of the blade.

The angles, typically around six to ten degrees on each face, play a critical role in cutting the grass effectively. These angles dictate where the grass gets clipped, ensuring a sharp and clean cut. Even when dealing with a new bottom blade, grinding is essential to establish the precise angles and ensure the blade’s flatness.

Impact of Incorrect Bottom Blade Angles

Grinding Machines

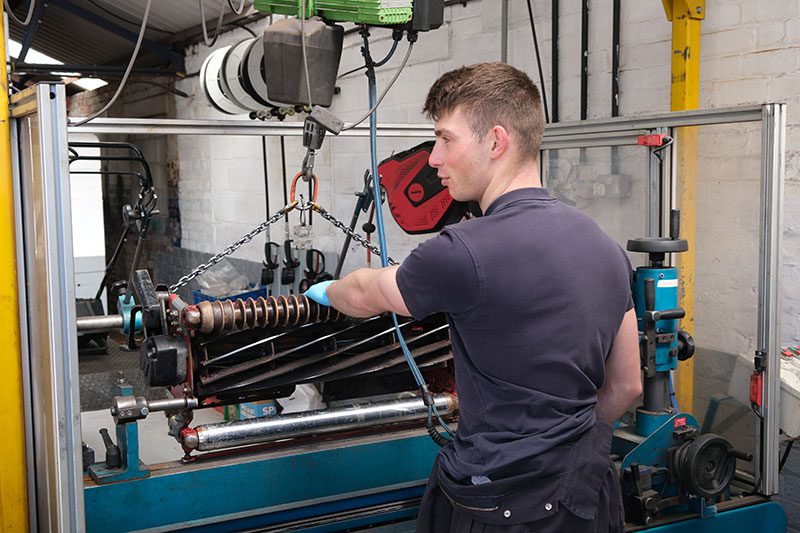

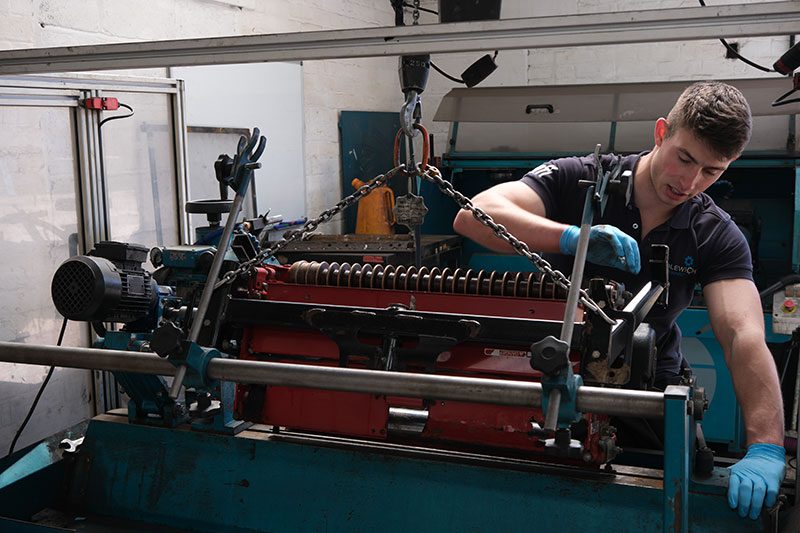

At Middlewich Machinery we use a Hunter Jupiter ATI All In One Grinder which you can spin and relief grind returning cylinders and bottom blades back to the original manufacturer’s specification. In addition we have a Hunter Amazon Series 5 bottom blade grinder which ensures accuracy and consistency in achieving the necessary angles and flatness required for optimal grass cutting. Its design and functionality cater specifically to maintaining the quality of the bottom blades, ensuring they are sharpened to the highest standards.

Key Points in the Cylinder Grinding Process

The primary goal of cylinder grinding is to restore the edge on the cylinder. Over time, the cylinder’s edge can round off, resulting in the blade losing its straight edge and becoming rounded.

The aim of cylinder grinding is to straighten out the blade and recreate a sharp, clean edge. This process also involves removing the cone-shape of the cylinder. While this wear naturally occurs over time, it can be accelerated by factors such as worn bearings or incorrect adjustments.

Various factors contribute to this rounding, including foreign objects entering the machine, with sand being a common culprit. Additionally, natural wear and tear from grass abrasion and general use also contribute to the rounding of the blade’s edge.

The initial step is cleaning. It helps us see everything clearly. There’s often a buildup at the back of the blade, almost like a fine layer of grass that accumulates. You might not feel it directly, but it hampers the blade’s efficiency. Cleaning involves using a hot pressure washer with a specific cleaning agent. It’s not like using your regular washing-up liquid! This process not only cleans the blades but also ensures there’s no grass buildup around the bearings and other critical parts.

The thorough cleaning allows us to physically inspect the equipment, especially checking for worn bearings that might exhibit play when moved. During the inspection, we ensure all the critical parts are in top shape, guaranteeing that adjusters are lubricated and moving freely. For instance, if you can physically manipulate the cylinder up and down, it’s a clear sign of wear and tear that needs attention. This step is crucial because if the parts aren’t in good condition, it can affect both the grinding process and the efficiency when cutting grass.

Once everything is inspected and confirmed to be in good order, we proceed to mount the equipment in the grinder. This can be done either in-situ, where the whole unit is mounted with its frame, or out of with just the cylinder on its own.

The cylinder grinding process involves measuring and gradually removing fractions of a millimetre at a time. While the visual change may not be apparent, the impact on the setup and cutting performance is significant.

Grinding begins by taking measurements at the centre of the cylinder on both sides. The initial step involves removing the rounded edge until the surface becomes flat. Once the flat surface is achieved, the focus shifts to consistently sharpening the edge to ensure it remains sharp.

Regarding the sharpening process, it’s not solely reliant on machinery. It involves a combination of sensory perceptions. The sound changes during grinding, serving as an initial indicator. This change in sound, considering the high-speed rotation (at around 3000 RPM), signals adjustments during the process. Additionally, the process involves tactile and visual assessment, relying on a keen sense of touch and sight to ensure precision.

The last steps involve reassembling, lubricating the bearings and adjusters with grease, and then setting up the equipment to ensure the correct height of cut (abbreviated as HOC) and ensuring the quality of cut, which is often assessed using a piece of paper to gauge sharpness and precision.

Here is a snapshot of our grinding inspection and quality checks

- Cleaning the equipment thoroughly to spot any issues clearly.

- Checking for worn bearings, ensuring all adjusters are well-lubricated and movable.

- Identifying worn bolts that might cause damage during the grinding process or affect grass cutting.

- Mounting can be either in-situ (with the whole unit and frame) or out-situ (just the cylinder).

- Spin and relief grinding

- Reassembling the components after mounting.

- Lubrication: Applying grease to bearings and adjusters for smooth movement.

- Setting up the equipment, ensuring the correct Height of Cut (HOC) and Quality of Cut (using a piece of paper for assessment).

Cylinder and Bottom Blade Replacement Frequency

Considering the wear and tear, the cylinder is reground multiple times and can last around 5-6 years or 2000 hours before being replaced, depending on usage frequency and grinding practices.

Most bottom blades are replaced annually. For a Greens Mower, bottom blades are often changed and sharpened at least twice a year. Conversely, for a fairway unit, the bottom blade replacement might occur just once a year. However, the grinding process for fairway units might be done multiple times a year, reusing the bottom blade by resurfacing it.

The Difference between Spin and Relief Grinding

Spin grinding encompasses the process of aligning, refining, and honing the blade to perfection. It involves rectifying any irregularities, eliminating the cone effect, and ensuring a precise sharpness along the blade’s edge.

Following spin grinding, we recommend an additional stage which is relief grinding. This procedure involves removing the rear part of the blade and this helps reduce contact on the bottom blade.

Unlike the entire surface wearing down, the impact zone narrows with time. For instance, as the initial edge wears off and rounds, instead of losing the entire cutting surface, it gradually moves through stages, retaining some efficiency until it’s fully depleted. This elongates the functional life of the components.

Moreover, the nuances of contact and non-contact between these parts contribute significantly. Essentially, a reduced contact area translates to diminished wear and resistance.

Consequently, the motors don’t need to operate at high speeds or intensities. This gains significance with the shift toward machine electrification, including the adoption of electric, hybrid, and especially battery-powered machines.

The more strain and resistance applied to it, it’s akin to an electric car towing a heavy trailer—your mileage decreases. Similarly, in our case, more resistance on the cutting edge means the motor requires additional power. This results in heightened heat production within the motor and the battery, significantly reducing the runtime. That’s why relief grinding becomes critical as we transition towards machine electrification.

In summary, relief grinding means cylinders last longer and therefore saves money. Not everyone undertakes this practice, but for us, it’s a distinguishing factor that adds substantial value.